ZF, whom you may know as the supplier of auto ’boxes for most luxury brands, has unveiled a new generation of modular electric drive units aimed at mainstream manufacturers. The line-up will be available from 2025 and includes new designs of electric motor-generators, a new type of EV transmission, inverters (the power electronics that sit between AC motors and DC batteries) and the software to integrate the whole lot.

First, let’s look at the motors. These are claimed to be smaller, more efficient, more sustainable, more power-dense and more affordable to make than the status quo.

There are some facts to bear out those claims. For instance, the cooling technology and design of the copper windings are new. There’s a cooling water jacket around the stator of permanent magnet motors (the bit that doesn’t move, containing the copper windings that generate electromagnetic fields). And deeper inside, there are slots that carry ZF Ecofluid E, a coolant oil that doesn’t conduct electricity (dielectric) and is in direct contact with the windings.

The design of the windings has changed as well, moving away from the popular hairpin style, so called because they’re made up of lots of hairpin-like pieces of wire joined by hundreds of welding points. Instead there are braided windings formed in one step and having only 24 welding points. The winding head, where the joins are made, is smaller and less bulky, at 15mm rather than 28mm. The slot cooling means the motor can run continuously and harder than before, at more than 85 percent of peak power.

Heavy rare-earth elements are reduced to as little as 1 percent, and that’s made possible by the improved cooling. The new design of the windings reduces the total length of a motor by 10 percent, increases power and torque density and reduces the amount of raw materials used by 10 percent. As well as the permanent magnet motors, there are magnet-free asynchronous motors and separately excited motors.

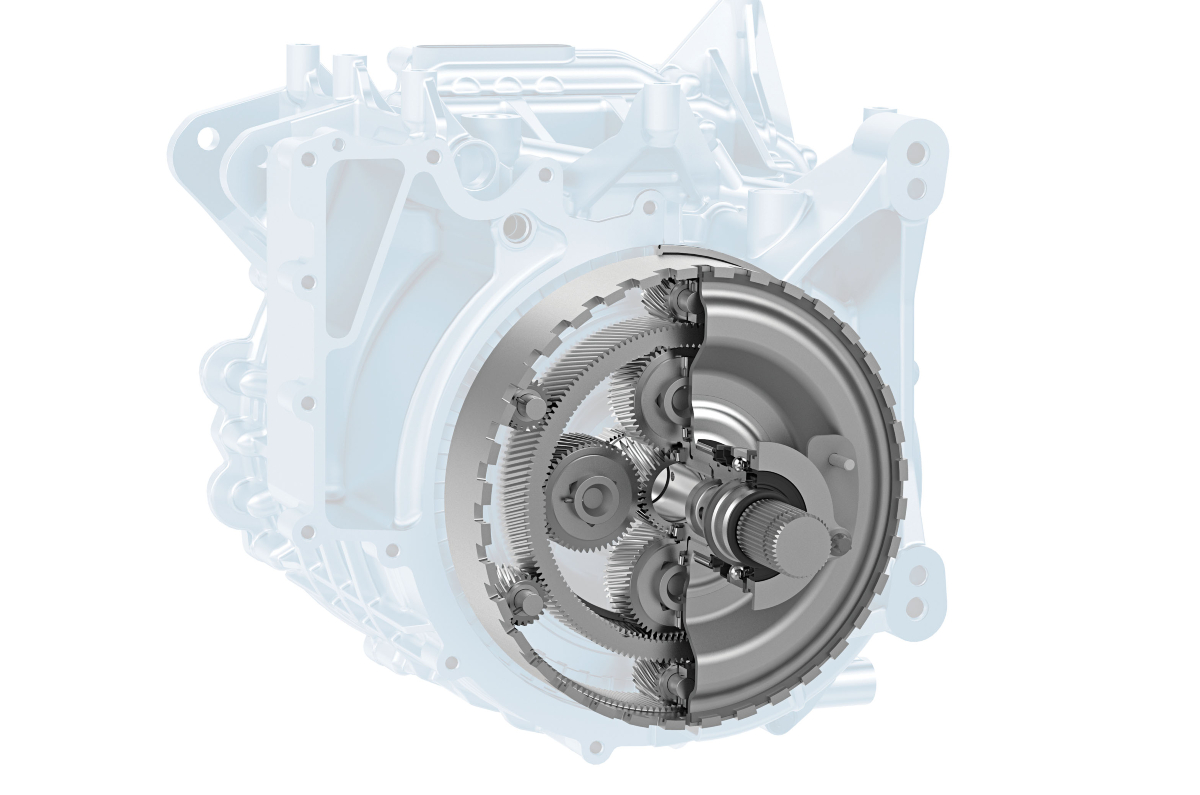

The transmission design is quite a departure from the norm, too. From 2011, ZF’s EV transmission consisted of a fairly typical two-stage gearset, stepping down the high revs of the motor once in the first stage and again in the second stage. Drive was then transmitted to the wheels through a separate differential. The new transmission comprises a stack of two planetary gearsets (so one inside the other) and also does the job of a differential. It’s based on similar technology that ZF introduced in the front-wheel-drive 9HP automatic transmission back in 2011. The result occupies 25 percent less space than the current offset designs, weighs 10 percent less and suffers 20 percent fewer transmission losses. At the same time, noise and refinement equal the existing technology.

The integrated drivetrains will handle a range of tasks, from 136hp secondary drives (in dual-motor installations, for example) to 407hp primary drives.

Because the internals are standardised, ZF says they can be quickly adapted to suit new vehicles as they come to the market.

In Perfect Unison

A technology from Continental with the snappy moniker CoSmA UWB is an ultrawide-band transceiver that closely ties your smartphone to your car. The device can spot your phone approaching and unlock the car, but the device’s ability to precisely locate the phone is so pin-sharp that it’s said to prevent thieves from intercepting the signal. It’s used by BMW in the iX, and the brand likes it enough to have given it an award.

Tech Talk: How Audi's new tech reduces atmospheric CO2

Tech talk: How Bentley has reimagined seating technology

from Autocar Indiahttps://cdni.autocarindia.com/ExtraImages/20230117033552_ZF_EV_powertrain.jpg